In theory, many things look possible. Practical application is a whole new ball game where things rarely play out to plan, the efficiency of your design notwithstanding. Similarly, corrective maintenance becomes necessary regardless of how efficiently you undertake preventive maintenance. The course of action during corrective maintenance is based on multiple factors.

When Corrective Action is unavoidable . . .

In our previous article, we discussed how to avoid risk or damage to the mould. In case you missed this article, you can find it here: Mould Lifecycle Management (MLM)- Preventive Maintenance

But then, there is a fatigue limit to everything, and issues do arise in the lifecycle of a product no matter how hard you try to prevent them. What if a non-conformity is detected during a routine quality check of a plastic part? Or if the supplier delivers a mould with a blocked cavity? And what if during production, the situation suddenly worsens, forcing you to block multiple cavities, and your mould maintenance team requests you to buy a new mould?

As the mould owner, you are concerned about getting the mould back in production at the earliest possible. However, before making a hasty decision, you must assess if the mould requires replacement or refurbishment.

You have a few choices to consider under corrective maintenance:

- Refurbishment: This means taking the mould down for a major overhaul along with the replacement of its components and/or rework on mould steel to transform it into a production-ready state.

- Replacement: You may want to replace the existing mould, especially when it is near the end of its life.

- Repair: Is a corrective action that includes the repair of worn-out mould elements and the replacement of mould spares and consumables.

How would you identify if the mould needs a refurbishment or replacement?

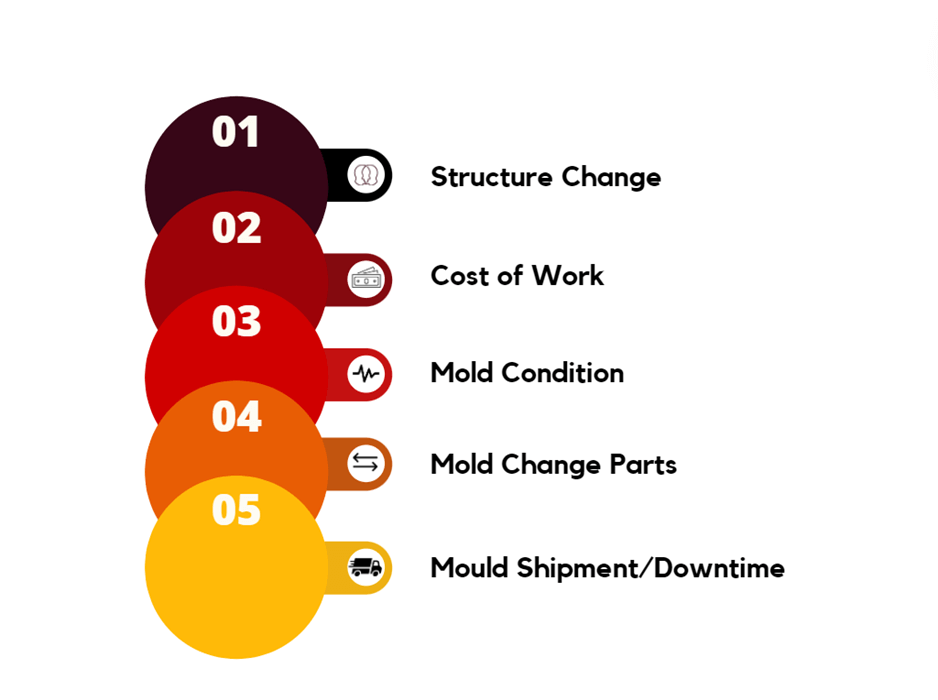

Such a call can be tough and depends on several factors. We have devised a checklist you may refer to when deciding on the matter:

- Structure Change

It is worth checking if you are expected to produce plastic parts from the mould in the future or if your customer is planning a new structure/product design change to replace the existing one. This will impact the course of action as it confirms the amount of time you would expect the mould to be in service:

- Repair – Recommended if the new structure/design change is expected to be implemented within the next 2 years.

- Refurbish – Ideal if the new structure/design change is expected to be implemented after 3-4 years.

- Replace – Suggested if the new structure is not expected to be implemented for at least another 4 years or more.

- Cost of Work Is another important factor. Here are the options:

- Repair – Is the best course of action for minor work that does not cost a substantial amount when compared to the original mould’s cost.

- Refurbish – Is recommended for intense work whose expenses can total up to 60% of the mould cost*.

- Replace – Is suggested if the repair and replacement cost is more than 60% of the mould cost*.

- Mould Condition, particularly the number of times it has been refurbished

- Repair – If the mould is relatively new and has less than 4MM shots.

- Refurbish – In case the mould has run over 4MM shots and if it has been fully refurbished only once or never.

- Replace – If the mould has been fully refurbished on two prior occasions.

- Mould Change Parts refers to whether or not major mould parts have been replaced earlier

- Repair – None of the major parts or components have been replaced earlier.

- Refurbish – Stacks (full cores and cavities) have been replaced along with the other necessary changes.

- Replace – New mould is built.

- Mould Downtime is the duration for which the mould will be out of action. Your choice will be based on whether you are comfortable with the associated downtimes

- Repair – If:

- These can be conducted locally at your own tool room; or

- The mould maker can ship the new components, or you can ship the old components to the mould maker for rework.

- Refurbish – Takes the mould out of action for a significant amount of time (10-15 weeks) as you may have to send it back to the mould maker

- Replace –You incur zero tool downtime since the new mould is immediately deployed for the production

After checking all five criteria, the path to follow will be clear.

Mould Qualification After Corrective Action

Based on the corrective action plan that you use, the mold qualification varies and is to be confirmed and approved by all the relevant stakeholders.

For a repeat mould, the qualification plan is similar to how a new mould is qualified. Find out all on new mould qualification in our article at: Mould Lifecycle Management (MLM)- Commissioning.

In the case of a mould refurbishment, it is not necessary to go through a thorough process of qualification. It depends on whether the mould surfaces were worked upon during the refurbishment. If yes, then a validation must be carried out to ensure the plastic parts are in conformance with the required specification.

If the plastic forming steel surfaces of moulds are not reworked, then the qualification plan may include comparing the aesthetic, dimensional, and functional aspects of the plastic component before and after refurbishment. The same can be checked and inspected by relevant stakeholders and approval can be shared. The same could be the case for mould repairs

Efficient delivers a unique and highly professional experience in managing mould refurbishment projects. To date, we have successfully managed countless moulds for our clients. Get in touch with us at www.efficientinnovations.in to know more.